- About

- News

- Advantage

- Technology

-

Products

-

Catalyst

View all products -

Equipment

View all devices

-

- Career & jobs

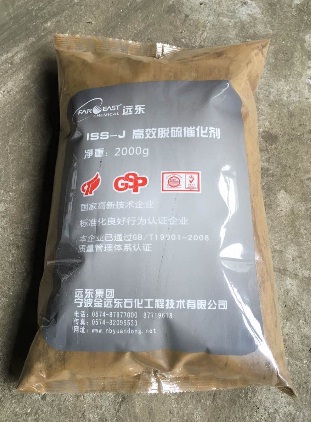

1, Catalyst

1) .ISS desulfurization catalyst

ISS series of desulfurization catalyst is a hi-tech product with an independent intellectual property rights(invention patent number: ZL02 1 12888.x), with high catalytic activity and low salt formation rate.

ISS-J desulfurization catalyst is developed by our ISS-Ⅲ ammonia-based desulfurization catalyst for the development of new coke oven gas desulfurization catalyst. Coke oven gas is a high hydrogen sulfide and hydrogen cyanide containing industrial gases, high dust and tar content. The current desulfurization efficiency of various desulfurization catalyst is not high, especially the high amount of vice-salt and waste . Our special catalyst is designed for the existing problems. ISS-J desulfurization catalyst are with new additives (tannins), iron complexes and other active ingredients compound.

1. The addition of new auxiliaries is with the following key functions:

(1) Increasing the capacity of catalyst to carry oxygen, accelerating the rate of catalyst regeneration, improving the conversion rate of ISS catalyst and improving the utilization efficiency of effective components directly ;

(2) Reducing the surface tension of the sulfur particles, improving the surface properties. The size of sulfur particle increases, making it easy for flotation separation and reducing the suspension of suspended sulfur;

(3) Improving the complexation of iron, reducing the consumption of iron complexes and also improving the utilization efficiency of ISS catalyst. At the same time the purification degree of H2S has also been improved and stabilized;

(4) The sulfur capacity of the catalyst is increased, the "curing degree" of HS- is improved and the side reaction generation rate is controlled further in the process of sulfur absorption reaction. In addition the alkali consumption is decreased greatly;

2. Tannin are treated by special technology to strengthen the oxidation and complexation ability, it can form a stable iron complex ions with ISS which is not easy to degrade.

In the process of desulfurization reaction absorption, ISS oxidizes HS - to generate element sulfur, the reduced ISS2 + in the regeneration process is oxidized to ISS3 +which recovers the oxidative recycling. In the absorption stage, most of the HS- are formed to elemental sulfur, the curing degree is high and the proportion of HS- ions entering the regeneration process is very small. The industrial application results show that the generation rate of the side reaction is greatly reduced and can be controlled within 3%.The desulfurization waste liquid is reduced greatly and the alkali consumption is decreased.

3.ISS-J desulfurization is the binary catalytic oxidation desulfurization, the hydrogen sulfide in the coke oven gas meets the desulfurization liquid in the desulfurization tower, then hydrogen sulfide is absorbed by the desulfurization solution to generate NH4HS or NaHS and forms the HS-, most of HS - has been oxidized to elemental sulfur by the ISS3 + in the desulfurization liquid before entering the regeneration, ISS3 +is reduced to ISS2 +. After entering the regeneration tower, ISS2 + contacts with air and are oxidized to ISS3 +. A small amount of HS- in the desulfurizing solution which has not been oxidized by ISS3 + is continuously oxidized by oxygen in the regeneration tower (regeneration tank) to thiosulfate and others.

Before the process of regenerating ,when the HS- is oxidized to sulfur by of ISS3 +, almost no secondary salts are formed such as thiosulfatedue to the absence of oxygen . After entering the regeneration tower(regeneration tank), a small amount of HS- which is not oxidized by ISS3 +will be oxidized continuously. Due to the presence of a large number of oxygen, HS-is oxidized to sulfur and thiosulfate and so on. The desulfurization secondary salts are produced in the presence of a large amount of oxygen in the regeneration process, and the ISS-J desulfurizer has oxidized most of the HS- into elemental sulfur before regeneration. Therefore, the ISS-J desulfurizer produces less secondary salt than that of Cobalt series desulfurization agent

The desulfurization reaction mechanism is:

1.Hydrogen Sulfide Absorption:: ![]()

![]()

2.Regeneration process::

ISS2 + Regeneration:: ![]()

ISS3 + oxidation to make sulfur:: ![]()

3.Desulfurization side effects::

(1) side reaction to form thiosulfate (S2O32-salt) and sulfate (SO42- salt)

![]()

![]()

![]()

(2) the side reaction of the formation of NaCNS salt

![]()

![]()

![]()

![]()

D (ox) represents the oxidation state of tannin, and D (re) represents the reduced state of tannin.

Secondly, there is a large amount of ISS3 + in the desulphurized lean liquid, and the oxidation of HS- by ISS3+ is fast, it starts from the desulfurization absorption process. The HS-ions are removed and the absorption driving force is increased, which improves the absorption rate ,the desulfurization efficiency and the degree of gas purification.

(A), The usage of ISS-J desulfurization catalyst

1, The process conditions

Ammonia is the alkali source, H2S content in the purifying gas is ≤ 20mg / Nm3

Analysis of ammonia: 0.3 ~ 0.6N

Alkalinity of the solution pH = 8.4 ~ 9.2

The temperature of gas inlet: ~ 27 ℃

Desulfurization temperature : 25 ~ 32 ℃

Regeneration temperature:30 ~ 35 ℃

soda Ash(or liquid caustic soda) as the alkali source, H2S content in the purifying gas is ≤ 10mg / Nm3

Total alkalinity: 0.3 ~ 0.65N

Alkalinity of the solutionpH = 8.2 ~ 9.2

The temperature of gas inlet :25 ~ 38 ℃

Desulfurization temperature : 31 ~ 45 ℃

Regeneration temperature: 31 ~ 45 ℃

2, The performance parameters:

1) High degree of gas purification. For the desulfurization of hydrogen sulfide content less than 5g / Nm3the first desulfurization will make hydrogen sulfide content in the purification gas become not more than 20mg / Nm3;

2) Be the binary catalytic oxidation desulfurization agent. In the desulfurization process, 80% of the HS- are converted to sulfur before entering the oxidation regeneration tank , the side reaction generation rate is only about 1/10 of the unitary oxide desulfurization catalyst;

3) Except the high efficient removal of hydrogen sulfide , this product can also be used to remove the hydrogen cyanide and organic sulfides; the sulfur particles are big in the sulfur formation process with easy separation and recovery from the solution.

(二)、The results of using of ISS-J desulfurization agent in the ammonia desulfurizaton

(B), In the ammonia desulfurization process, a large number of ammonium thiosulfate and ammonium thiocyanate are produced in the absorption and regeneration process, these ammonium ions will affect the absorption rate of hydrogen sulfide and purification seriously .

The absorption reaction equation:![]()

:

Equilibrium constant:![]() :

:

The equilibrium partial pressure of hydrogen sulfide :![]()

:

In the desulfurization of coke oven gas, in order to minimize the amount of desulfurization discharge and reduce the environmental pressures, the secondary salt content needs to be improved as much as possible( for thecoking plant with sub-salt device ,in order to reduce energy consumption during the process the content of the secondary salts should be as high as possible).There is a large number of ISS3 + in the ISS-J catalyst desulfurization poor solution, it reacts with HS- in the absorption tower in the absorption process .The HS- in the absorption solution is removed in time, reducing the content HS-in the absorption liquid , also reducing the balance partial pressure of the of hydrogen sulfide . Therefore ISS-J desulfurization agent still has a very high degree of purificationin the high content of secondary salts condition. In the desulfurization liquid of Shandong Yanzhou International coking the secondary salt content is up to 400 ~ 500g / L, the hydrogen sulfide content in the sulfuric acid tower outlet is stable at 20mg / Nm3 below.

In order to improve the desulphurization efficiency and reduce e consumption of desulfurization (catalyst, alkali source, power and labor), the desulphurization catalyst auxiliary agent is developed in combination with wet oxidation desulfurization technology and the property of the existing catalyst and ISS series catalyst. The auxiliary agent can be used in combination with other catalysts or independently.

ISS desulfurization tower cleaning agent

The ISS desulfurization tower cleaning agent is a kind of new tower cleaning agent which has been tested and researched by our company for many years. It is invented by our senior engineer Mr Chuan-Jun Zhao. There is no corrosion to the equipment and no effect on the desulfurization efficiency and the alkalinity of the solution. It can be used easily to remove the impurities in the purifying tower, the tower packing, the gas liquid distributors and pipelines. This product can be added normally to avoid the plugging of the tower; It can also be added as a tower cleaning agent in the case of sulfur blocking.

1, The main purpose is to remove the impurities which is adhere to the desulfurization tower packing, tower, gas liquid distributor and the sulfur impurities in the pipeline, which will reduce the desulfurization system resistance. Usually when the tower is blocked by the sulfur the tower are forced to stop for the cleaning ,which will affect the continuous production. By using our tower cleaning agent this problem can be solved completely.

2Using method

In the case of normal operation of the system it can be added to the desulfurization solution directly to dissolve, the amount is determined according to the degree of system resistance to. Generally 3-15 days after the accession the tower of sulfur on the pipeline can be removed completely or partially and the impurity content reaches the standard. At the same time, after the addition the resistance of the system will stop rising, the removal rate is 95% or more. The specific adding amount is determined by the system resistance, on-site problems, the size of the solution and the solution composition.